LIBRECAD CONSTRAINTS SOFTWARE

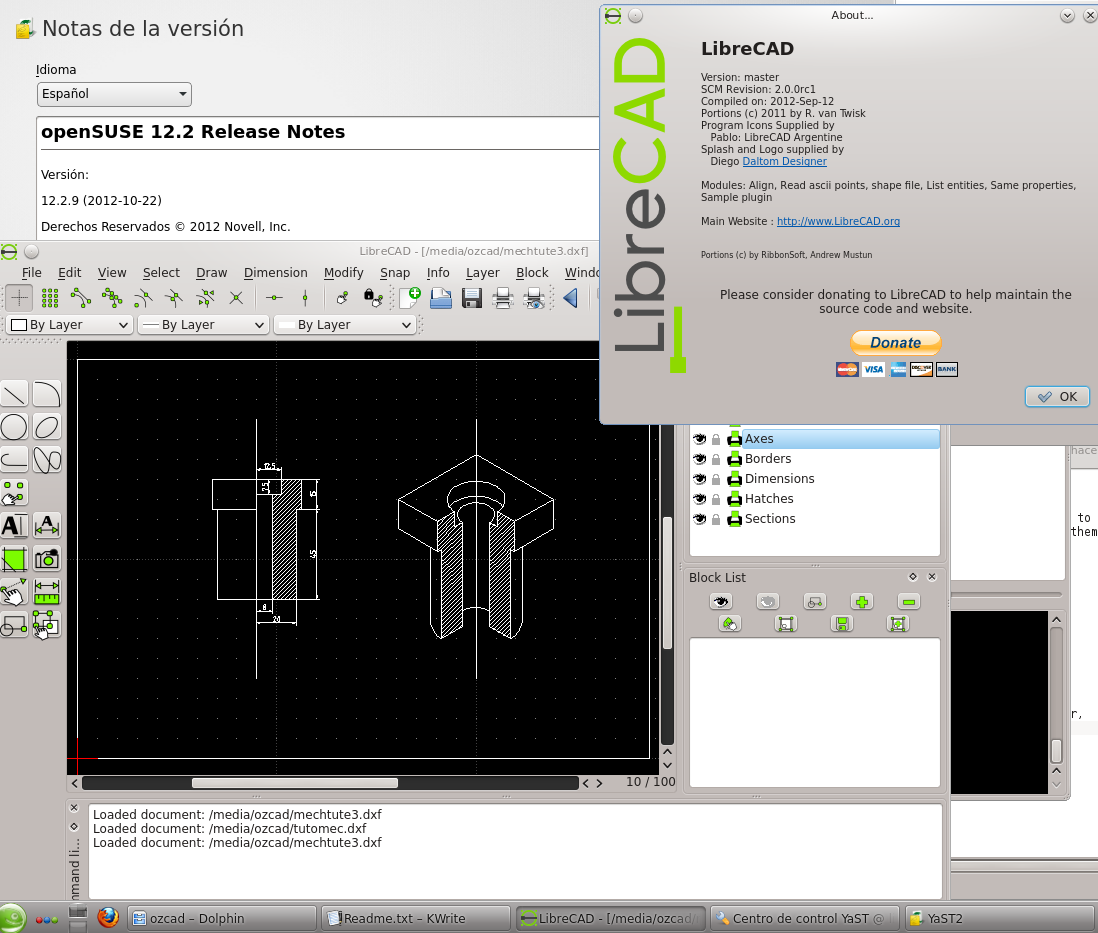

Non-parametric design I designed the piece to assemble with press-fit thickness of 4,65 mm. These are the links to the and in LibreCAD. I cut another wood piece with notches of: 4,75 mm, 4,70 mm, 4,65 mm, 4,60 mm kaj 4,55 mm. I cut the wood with notches of different thicknesses: 5,2 mm, 5,1 mm, 5,0 mm, 4,9 mm kaj 4,8 mm. It could be caused by the direction of the wood fibers. The error is 0,03 mm in one direction and 0,26 mm in the other. Mesurement with caliper This tells us that the first time it was more precise. I tested with higher speed (10 mm/s) at 75% power. With this design I cut a wooden square of 5 mm thickness. This link provides the above in LibreCAD. The process I followed on LibreCAD for designing the gauge piece was by drawing orthogonal vertical and horizontal lines as follows. It has different press-fiting gauge cuts for determining the width of the cut according to the thickness of the material.

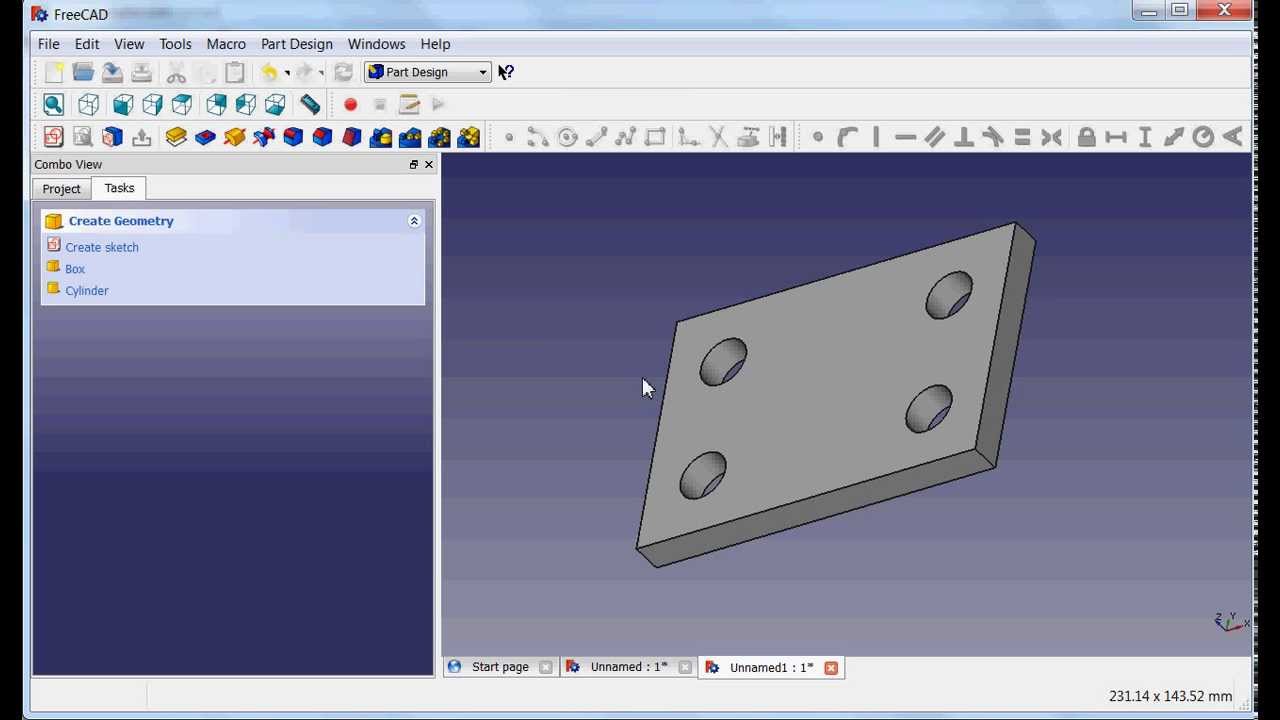

So it must be used with an exact startup procedure. In this nice bar we have also horizontal and vertical constraints and the zero. TUTORIAL Drawing a little mechanical part using LibreCAD Tutorial by Claudio. The light reflects on CO 2 gas and shoots in a beam of parallel rays. The machine has a long tube that shoots light. The cutting machine works with a CO 2 LASER (Light Accumulation by Stimulated Emission Rays). LASER cutting Technology I have learned cutting by control of the computer. Computer controlled cutting can be also be achieved with the CNC mill as described in the and the image shown below. Computer-controlled cutting can make 2D pieces in order to construct 2D objects or or for integrating them and making 3D objects as can be seen on this skull.

I will also detail how and what interfaces I used for connecting the cutting machine to my computer. The press-fit pieces process is described. I will hereby, describe the software used to design and how I calibrated these machines and cut these pieces. Quiliro's Assignment: Computer controlled cutting Computer Controlled Cutting This assignment will lead us through computer-controlled cutting with a LASER machine and a vinyl cutter.

0 kommentar(er)

0 kommentar(er)